Home >

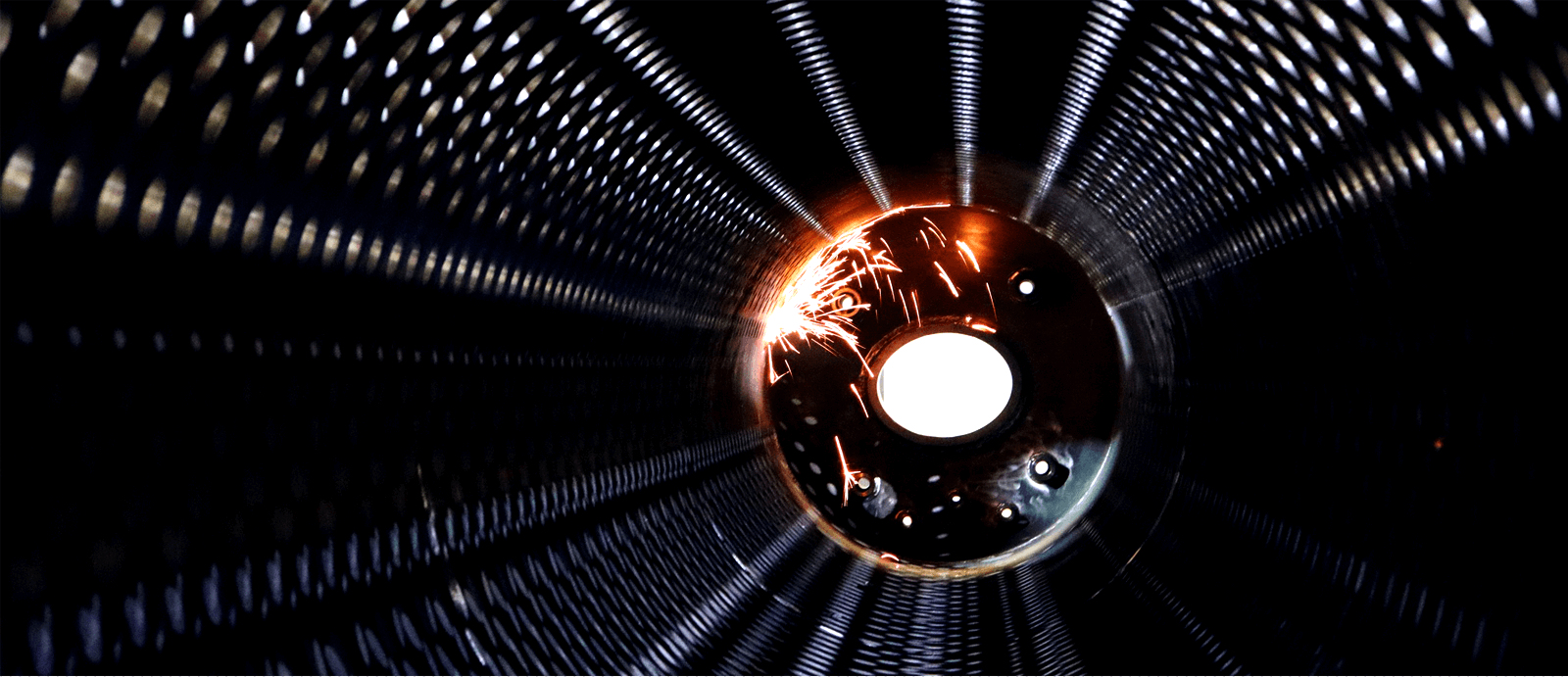

When it comes to boilers, flexibility and resourcefulness are king. That's why we work side-by-side with our customers to build the boiler they need, not the one that's easiest for us to make.

✓ Fluctuating load demands

✓ Fuel flexibility

✓ Emissions compliance

✓ Redundancy

✓ Energy efficiency

✓ Footprint challenges

We offer an extensive variety of boilers with unique features to fit a variety of applications. To quickly find the right boiler for your application, choose your criteria and let Superior Search help you find the right fit for you.

No matter your environmental concerns or regulations, our team of superior problem solvers can recommend a boiler system that functions best for your needs. We specialize in:

Reducing electrical demand

Using renewable energy

Lowering NOx and CO2 emissions

Reducing water usage

From deaerators and control panels to economizers and more, we've got the equipment and accessories you need to outfit your boiler room.

Learn More

Superior Boiler is very responsive, and that's why we choose to use them for more than just heating and cooling.-Jack Graber, VP Exhibits & Technology, Cosmosphere