A steam separator, sometimes called a moisture separator or a steam drier, is a device used to separate the moisture from the steam in a watertube boiler steam drum. Without the steam separators, ‘wet’ steam would be released from the watertube boiler and create a multitude of problems during boiler operation and the following equipment, including decreased productivity and efficiency and increased erosion and corrosion rates. Because of this, steam separators are critical to a watertube boiler’s proper operation.

The primary steam separator, which includes panels, sometimes called baffles, located at the bottom and sides of the steam drum, works to separate the water by a mechanical separation process, before recycling the water back into the boiler as a part of the natural circulation process.

Typically, a watertube boiler, like those manufactured by Superior Boiler, has both a primary and secondary steam separator, working together to achieve 99.9% steam quality in the boiler, depending on the requirements set forth by a customer’s needs and process. Generally, the primary and secondary steam separators with the internal piping are all housed in the steam drum, a very confined space in the boiler with limited room to work and install internal equipment.

Why is a Steam Separator Necessary?

Steam separators are a vital part of steam watertube boilers to increase steam quality to the requirements dictated by the customer’s process. The steam quality produced by the boiler affects thermal efficiency and increases the likelihood of erosion in a production process. Decreased thermal efficiency creates the need for increased heat to maintain the required steam output. This increases the energy and operating costs required to run the boiler according to the facilities’ needs.

Wet steam also exposes a customer’s piping, steam valves, and other downstream equipment to increased risk of corrosion and erosion, leading to costly repairs and downtime. For superheated units that include the superheater integrated into the boiler, steam dryness is required to prevent internal corrosion and intercept solids before they carry over into the superheater, which can reduce heat transfer and cause tube failures. Any moisture content in the steam that passes through the superheater leads to rapid corrosion of the steam coils inside the equipment, decreasing the lifespan of the superheater and creating additional costly repairs to get the system back up and running.

The water particles found within the steam can also house dissolved solids, which can cause many issues in the following process. The dissolved solids carried in the steam may contaminate the process that follows, including but not limited to processes ranging from food manufacturing to brewing and distilling to the sterilization of equipment in hospitals and research facilities. The solid particles also cause steam pitting on steam turbine blades in electrical generation applications.

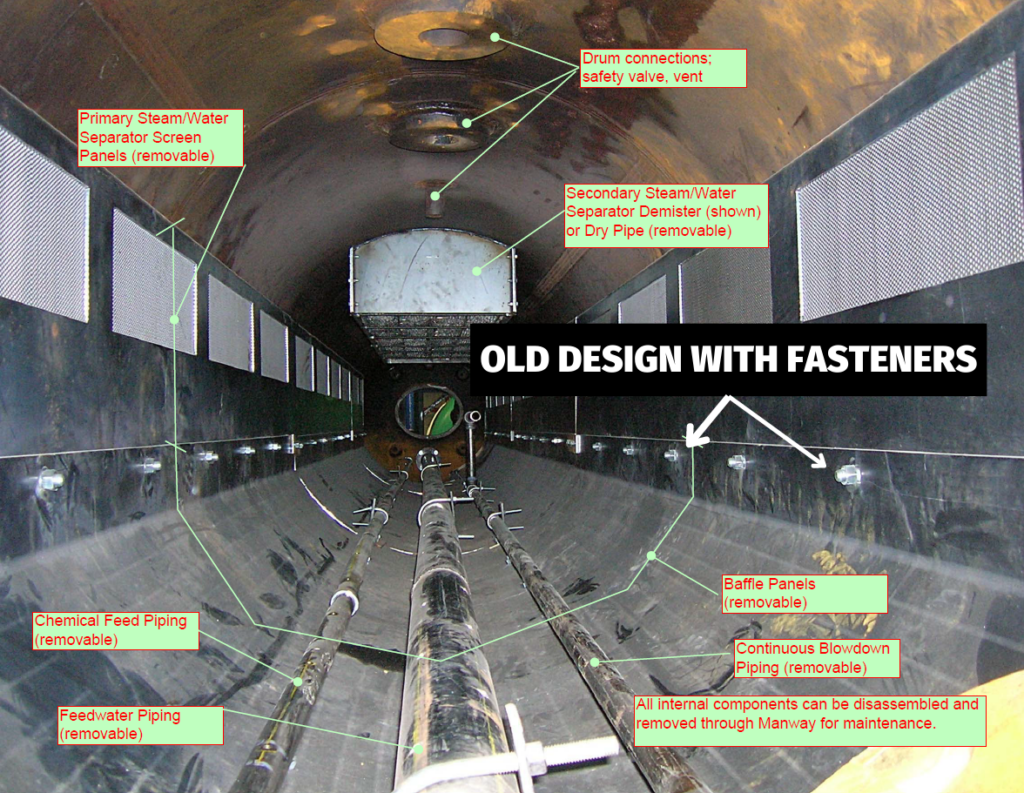

Though the steam separator is a key part of the watertube boiler’s ability to meet customers’ steam quality requirements, it can cause its own problems. During a typical installation, the panels are welded using a series of clips inside the drum at select locations and are aligned to holes on the panel. These are then fastened with bolts and nuts. Due to the space constraints of the steam drum, the process of securing the panels in and of itself is challenging and time-consuming, increasing production time and costs.

During regular operations, the fasteners used to secure the panels to the drum are submerged in water and prone to becoming fused together. This becomes an issue when drum internals have to be disassembled to provide access to the steam drum tubes, such as during yearly inspections and routine maintenance. Each year during inspections, the fused fasteners will have to be cut apart and then replaced upon completion of the inspection, increasing the time and costs required for the boiler’s planned downtime.

The design of the drum internals themselves is also critical to allow access for inspections due to the limited space of the boiler manways. Each panel must be able to fit through the American Society of Mechanical Engineers (ASME) standard 12-by-16- inch manway while maintaining a size and weight that is manageable by a boiler maker in a confined access area, creating additional hurdles for innovations to the critically important steam separators. Most steam separators consist of one or two large panels that are welded to the boiler, creating extreme difficulties for a single boilermaker to remove and inspect the boilers.

New Design Addresses Previous Steam Separator Challenges

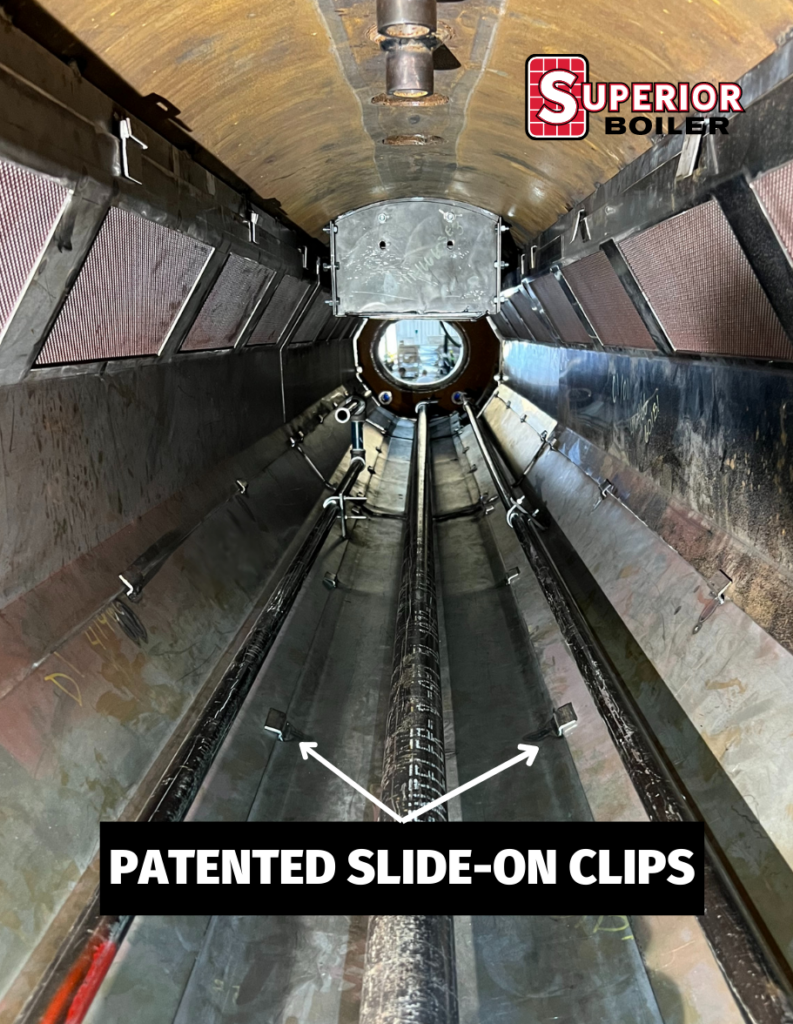

Superior Boiler’s new patented design for the primary steam separator maneuvers around the fastener and inspection obstacles. The improved steam separator design works to address fabrication and maintenance challenges by introducing a slide-on clip arrangement with the panels in lieu of the bolts, nuts and weld clips that were previously required. It takes advantage of gravity, drum geometry, and the weight of the panels to secure the panels to the steam drum. By using this design, no bolts or hole alignments are needed, and the amount of welding required inside the drum is significantly reduced. Superior’s patented design allows the use of smaller panels that, in combination with the slide-on clip arrangement, are easier to remove for inspection and maintenance. The innovative slide-on clip arrangement also reduces the shop installation and the field removal and installation time for the drum internals, which will save an end user time and money.